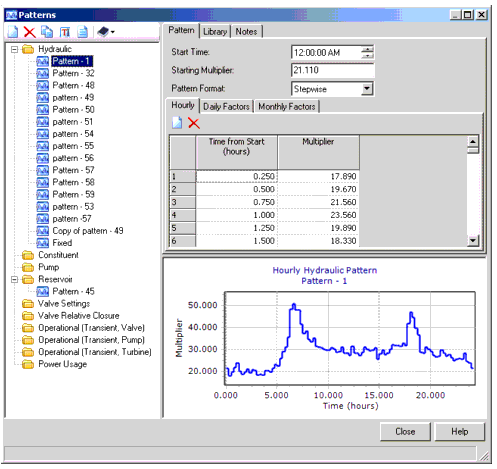

Pattern Manager

A pattern is a series of time step values, each having an associated multiplier value. During an extended period analysis, each time step of the simulation uses the multiplier from the pattern corresponding to that time. If the duration of the simulation is longer than the pattern, the pattern is repeated. The selected multiplier is applied to any baseline load that is associated with the pattern. You can also define daily and monthly multipliers for any pattern.

Patterns provide an effective means of applying time-variable system demands to the distribution model. The Pattern Manager allows you to create the following types of patterns:

- Hydraulic—This type of pattern can be applied to Junctions or Tanks. Use this pattern type to describe demand or inflow patterns over time.

- Constituent—This type of pattern can be applied to Reservoirs, Tanks, or Junctions. Use this pattern type to describe changes in Constituent Baseline Loads over time.

- Pump—This type of pattern can be applied to Variable Speed Pumps only. Use this pattern type to describe changes in the pump's Relative Speed Factor. In the Property dialog box for the pump, Is Variable Speed Pump needs to be set to True and the VSP type needs to be Pattern Based.

- Reservoir—This type of pattern can be applied to Reservoirs. Use this pattern type to describe changes in HGL over time, such as that caused by tidal activity or when the reservoir represents a connection to another system where the pressure changes over time.

- Valve Settings—This type of pattern can be applied to valves. Use this pattern type to describe changes to valve settings over time.

- Valve Relative Closure—This type of pattern can be applied to valves. Use this pattern type to describe changes to the relative closure of a valve over time.

- Operational (Transient, Valve)—This type of pattern can be applied to valves. Use this pattern to describe changes in a valve's status over time during a transient analysis.

- Operational (Transient, Pump)—This type of pattern can be applied to pumps. Use this pattern to describe changes in a pump's status over time during a transient analysis.

- Operational (Transient, Turbine)—This type of pattern can be applied to turbines.Uuse this pattern to describe changes in a turbine's status over time during a transient analysis.

- Power Usage—This type of pattern can be applied to Power Meters in for use in energy management analysis.

The following management controls are located above the pattern list pane:

| New | Creates a new pattern of the highlighted type. |

| Delete | Deletes the pattern that is currently highlighted in the list pane. |

| Rename | Renames the pattern that is currently highlighted in the list pane. |

| Report | Opens a report of the data associated with the pattern that is currently highlighted in the list pane. |

| Synchronization Options | Browse the Engineering Library, synchronize to or from the library, import from the library or export to the library. |

The right half of the dialog consists of controls that allow you to define the settings for the pattern that is currently selected in the list of patterns on the left side of the dialog.

- Start Time—The first time step in the pattern. The start time format is a standard 24-hour clock. The format is Hour:Minute:Second AM or PM (e.g., 12:45:30 PM).

- Starting Multiplier—The multiplier value of the first time step point in your pattern. Any real number can be used for this multiplier (it does not have to be 1.0).

- Pattern Format—The following pattern formats are available:

- Stepwise—The multiplier values are considered to be the average value for the interval between the specified time and the next time. Patterns using this format will have a staircase appearance. Multipliers are set at the specified time and held constant until the next point in the pattern.

- Continuous—The multipliers are considered to be the instantaneous values at a particular time. Patterns using this format will have a curvilinear appearance. Multipliers are set at the specified time, and are linearly increased or decreased to the next point in the pattern.

Hourly patterns consist of a number of time step points, defined in the table below the Pattern Format control on the Hourly tab.

- Time From Start—The amount of time from the Start Time of the pattern to the time step point being defined.

- Multiplier—The multiplier value associated with the time step point.

- Relative Closure— The initial relative closure used at the start of a steady state or EPS run. (A relative closure of 0% means the valve is 0% closed, or 100% open. Conversely, a relative closure of 100% means the valve is 100% closed or 0 % open).

- Relative Speed Multiplier—The percentage of full speed that the pump is running at during the associated time step point. This attribute is only available for Operational (Transient, Pump) pattern types.

- Gate Opening Percent —The percentage compared to fully open for the turbine gate opening at the associated time step point. This attribute is only available for Operational (Transient, Turbine) pattern types.

Daily and Monthly factors are defined in the same way as hourly ones, the difference being that rather than defining time steps you enter multipliers for each day of the week (for Daily patterns) or for each month of the year (for monthly patterns).

A graph of the currently selected pattern is displayed in the lower right corner of the dialog.

Note: An Extended Period Analysis is actually a series of Steady State analyses for which the boundary conditions of the current time step are calculated from the conditions at the previous time step. This software will automatically convert a continuous pattern format to a stepwise format so that the demands and source concentrations remain constant during a time step.

An individual node can support multiple hydraulic demands. Furthermore, each load can be assigned any hydraulic demand pattern. This powerful functionality makes it easy to combine two or more types of demand patterns (such as residential and institutional) at a single loading node.